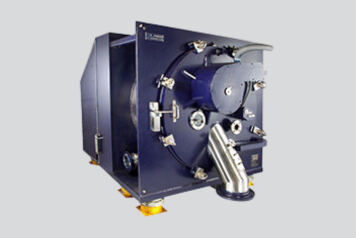

Horizontal Chemical Peeler

The Horizontal Chemical Peeler is a batch type automatic / semi automatic filtering centrifuge. The axis of rotation of the basket in this centrifuge is horizontal. They are used in many processes, primarily in the bulk chemicals and food industries.

Operation

-

Slurry Is Fed Into The Rotating Basket Using A Feed Pipe.

-

Cake Washing (Using A Wash Pipe) And Dewatering Cycles Are Carried Out.

-

Liquid Is Discharged Through A Discharge Pipe

-

A Scraper Knife Cuts The Solids Discharging Through Nozzle In The Lid / Cover.

Benefits

-

Flexibility - Chemical Peeler Centrifuges Can Be Adopted Easily To Changing Process Requirements. Different Control Recipes Can Be Used To Select The Optium Operating Speed And Cycle Sequence For Yieldling The Highest Product Quality At Peak Capacity.

-

Lower Residual Cake Moisture Due To High Centrifugal Forces.

-

Mounting On Anti Vibration Mounts Results In Lower Forces Being Transmitted To The Foundation

Optional Features

-

Cake Monitoring System

-

Vibration Monitoring System

-

Complete Automation Using PLC

-

Inerting System

Material Of Construction

Stainless Steel, Hastelloy, MS Rubber Lined, Fluoro Polymer Coating / Lining viz.- Halar (ECTFE), Teflon (PFA)

Available Sizes (Basket Dia ): 630 mm to 1600 mm (Special sizes can be designed on request)

Volume under Lip : 40-860 lit per batch

Max Permissible Load * : 40-860 kg per batch

Centrifugal Force : 800-2028 G units depending on size of Basket

Speed of Basket : 950-2400 RPM - depending on size of Basket

Note

Chemical Peeler Centrifuges is advised for a non-sticky crystalline product which can be easily cut by the scraper blade.